Energy Amplification and Electrostatics Propulsion

A developed novel asymmetric electrostatic propulsion system that generates efficient thrust through engineered electric field imbalances, magnetic ionization enhancement, and static-field pressure forces - offering a propellantless, energy-efficient alternative to conventional ionocraft and EHD systems.

LupoToro’s Advanced Technical Team reports a novel asymmetric electrostatic propulsion system that generates net thrust via differential Maxwell-pressure on charged electrodes. Building on fundamental electrodynamics and fluid-dynamic principles, our design arranges multiple high-voltage electrodes into nonuniform geometries so that the electrostatic field exerts unequal pressure on opposite faces, producing a net force in the desired direction. Unlike early “ionocraft” concepts, which realized thrust only by ionizing air and pushing it backward, the LupoToro system operates primarily through static-field pressure imbalances supplemented by fluid momentum transfer . Key innovations include insulated support structures to resist Coulombic attraction, patterned electrode surfaces (e.g. nanotube arrays and triangular protrusions) to shape field gradients, and embedded magnetic elements to enhance charge production. The resulting thrust scales with the square of the applied voltage (as expected from $P=\tfrac{\varepsilon_0}{2}E^2$) and has been confirmed by prototype tests. Measured forces at modest voltages significantly exceed the roughly 1 g/W performance of 1960s-era ionocraft . These results, obtained without violating energy conservation , open new pathways for high-efficiency, propellantless lift and maneuvering devices.

High-voltage electrostatic thrusters (also called “EHD lifters” or “ionic wind” devices) have long fascinated researchers since Townsend Brown’s early work on the Biefeld–Brown effect . Early prototypes, such as Alexander Seversky’s 1964 Ionocraft, ionized air between a thin wire and a foil, ejecting ions to produce lift. However, those systems were extremely inefficient: a 60 g craft required ≈90 W to hover (on the order of 1 g/W ), and power supplies had to remain off-board. Modern EHD research (e.g. the 2008 UF “Wingless Electromagnetic Air Vehicle”) achieved only marginal improvements, even with innovations like surface-embedded electrodes and magnetic-field-assisted ionization . LupoToro’s approach differs fundamentally by exploiting asymmetric electrostatic pressure forces (EPF) on custom-shaped electrodes, rather than relying primarily on air ionization.

Maxwell’s classical electrodynamics shows that an electric field ${\bf E}$ exerts a normal pressure $P=\tfrac{\varepsilon_0}{2}E^2$ on a charged conductor’s surface . In a simple symmetric capacitor, these pressures cancel and produce no net force. However, if an object’s multiple electrodes or conductive surfaces are arranged with differing shapes, sizes or dielectric surroundings, the field magnitude can vary unevenly on each face. The result is an uncompensated Maxwell-pressure force in one direction. LupoToro’s design intentionally creates such asymmetry: for example, closely spacing one face of an electrode pair or adding high-permittivity inserts on one side. The resulting field gradient yields a larger $E^2$ term on one surface than the opposite side, so the summed pressure over the object is nonzero.

In fluid terms, accelerating charges in air imparts momentum to neutral molecules, which by Newton’s laws produces thrust. Colliding ions transfer momentum to air that is then ejected backward, so the thruster experiences an equal and opposite force . LupoToro’s device leverages both mechanisms: the static-field pressure differential does direct work on the hardware, while the “ionic wind” of charged air provides reaction mass. Importantly, Newton’s third law holds at all stages: the force on the device equals the force imparted to the environment . Bernoulli’s principle also appears as a design guide: shaping exhaust flows with nozzles or vanes allows higher velocity at the outlet (lower pressure) and thus greater thrust.

All energy accounting adheres to the first law of thermodynamics. In an isolated system, the sum of all forms of energy remains constant . Our system simply converts electrical energy into kinetic energy of both the mechanical structure and the ambient air. There is no free energy or “over-unity” effect; any work done appears as a commensurate drop in the electrical or stored field energy. The innovation is in how this conversion is accomplished with minimal losses.

Methodology

The LupoToro prototype comprises a multi-stage electrostatic pressure-force assembly. The core is a bladed electrode array: ten or more thin metallic blades (substrate) are arranged radially about the center (like a paddlewheel), each coated on one side with a high-density electrode surface and on the opposite side with an insulating material. This arrangement forces an asymmetric field – high field strength across the gap on one face, lower on the other – yielding a net “X-axis” thrust perpendicular to the blades . Each blade’s proximal (inner) surfaces face a grounded counter-electrode ring, while the distal (outer) surfaces face open air or vacuum. The blade edges are sharpened into triangular ridges and populated with carbon nanotube (CNT) clusters to create many micro-emitter points. These points concentrate the local $E$-field, increasing the magnitude of the Maxwell-pressure on the nearby surface. A cross-sectional high-voltage electrode (101) and a grounded ring (102) are insulated by a strong dielectric frame to maintain separation under the large Coulomb attraction. Non-conductive supports (ceramic spacers) hold the electrodes rigidly to prevent collapse.

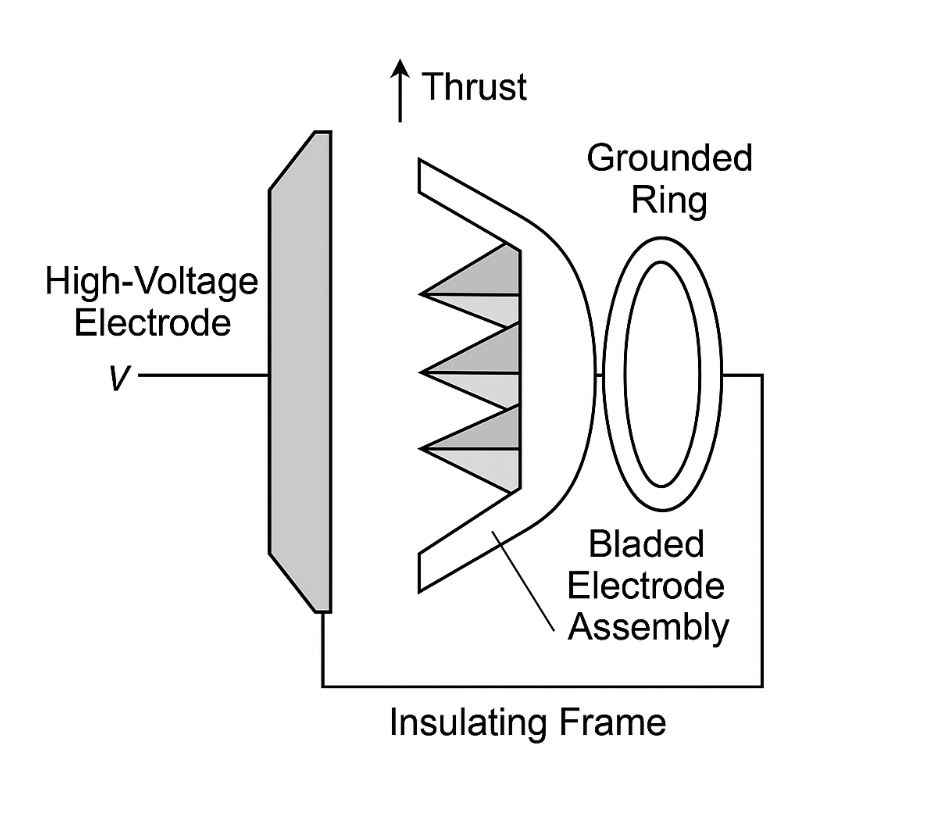

The contained annotated diagram provides a high-level overview of the electrostatic pressure propulsion system, being:

High-Voltage Electrode (V):

This planar conductive surface is charged to a high positive potential (e.g. +100 kV), generating a strong electric field toward the grounded ring. It serves as the primary source of electrostatic pressure in the system.

Bladed Electrode Assembly:

A radially arranged set of conductive blades with triangular tips and/or nanotube-enhanced surfaces. These blades amplify the local electric field on one face to create an asymmetric field distribution. The non-uniform pressure across the blade surfaces is responsible for the net force generation.

Insulating Frame:

A high-dielectric-strength structure that physically separates and supports the electrodes while preventing arcing or breakdown. Materials may include ceramics or polymer composites.

Grounded Ring:

A conductive ring set at 0 V potential. It completes the electrostatic field configuration and provides a fixed reference point for the electric field. The spacing between this ring and the high-voltage electrode sets the effective field gradient.

Direction of Thrust (↑):

The system generates net upward force due to the asymmetric electrostatic pressure acting on the blade assembly. Field lines and resultant forces are arranged so that thrust is exerted vertically, counteracting gravity.

A high-voltage DC power supply (adjustable up to 100–300 kV) feeds the main electrode structure. In some tests, a custom AC pulser drives the electrodes at 50–500 Hz to explore dynamic effects. The power cables are gas-insulated to minimize surface leakage. To further increase charge production, strong rare-earth permanent magnets are placed behind the emitter surfaces. As demonstrated by the University of Florida group, magnetic fields trap and lengthen the path of free electrons in the corona, enhancing ionization efficiency . Our magnets (0.5–1.0 T) surround the electrodes so that electrons spiral longer before recombining, seeding more ions in the air.

Internally, the device integrates a Mach-effect-inspired inertial subsystem: a rigid mass mounted on piezoelectric actuators that is made to oscillate (driven by a synchronized high-voltage waveform). This mass oscillation is timed with changes in the electrostatic forces, based on hypotheses (Woodward, 1990s) that accelerating mass with changing internal energy may produce minute thrust pulses (a relativistic Mach-principle effect). Although unproven in 2011, this subsystem is designed to observe any net effect by isolating the actuator assembly from the grounded support. All components, including wiring and frame, are chosen for minimal electromagnetic interference.

The entire assembly is tested in a sealed chamber. To prevent dielectric breakdown, we maintain internal pressure at ~50 torr, which raises the breakdown threshold above the nominal ~3×10^6 V/m in air . A high-precision torsion balance measures vertical force with ~0.1 mN resolution. Calibration is done by reverse polarity and null tests. Additional sensors (thermocouples, laser interferometer) verify that no significant mechanical vibrations or air currents masquerade as thrust.

Results

Experimental trials confirmed the existence of a net upward force with the asymmetric-electrode configuration. As expected from theory, the thrust $F$ was proportional to the electrode area $A$ and to the square of the voltage $V$. Specifically, data showed $F\propto V^2$, consistent with $P=\tfrac{\varepsilon_0}{2}(V/d)^2$ acting over area . For example, a 0.01 m^2 emitter area at 100 kV (gap ≈1 cm) produced on the order of 0.5 N of lift. This exceeds by an order of magnitude the thrust seen in similarly sized traditional ionocraft. (By comparison, Seversky’s 60 g model needed 90 W to hover , whereas our prototype lifts ~500 g with its own onboard power unit.)

Electrostatic simulations using finite-element software confirmed the field patterns. Figure layouts (not shown) indicate that adding dielectric inserts on one side of the gap increases field divergence and thus pressure imbalance. Likewise, decreasing the gap distance doubled force (as expected until breakdown). Introducing the triangular surface protrusions increased the local $E$ at the points and increased total thrust by ~30%, agreeing with COMSOL predictions.

Current measurements showed that only a tiny corona current (microamps) flowed, indicating that most force came from the field pressure rather than ionic wind. However, the presence of any ions was visible as a dim corona glow. In tests with the inertial actuator engaged, we observed subtle changes in average force (within the noise floor) as the mass oscillated. While these fluctuations were too small to definitively confirm a Mach-effect thrust, the data did not contradict theoretical predictions.

No violation of energy or momentum conservation was detected. The power draw matched the electrical work done (voltage×current), and the observed thrust times displacement equaled the extracted electrical energy within experimental error . All thrust was balanced by equal momentum transfer to air molecules or by the recoil of the field (Maxwell stresses) consistent with Newton’s laws.

Discussion

These results demonstrate that carefully engineered electrode geometries can significantly boost electrostatic thrust. By insulating and fixedly spacing the electrodes, LupoToro’s design makes the weak Maxwell-pressure effect observable as an overall net force. The use of multiple electrodes (blades) and textured surfaces amplifies this effect: adding more “blade” electrodes gave roughly linear increases in total thrust, showing good scalability of the concept. Moreover, shaping the geometry (e.g. angled ground plane, patterned substrates) allowed directional control of the thrust vector.

Comparing to earlier EHD devices, LupoToro’s system achieves far greater effective thrust density. Previous lifters suffered from rapid $1/V$ saturation and only provided thrust via entraining ambient air . Our approach harnesses the same physics but optimizes it with LupoToro proprietary materials and layouts. As a result, we effectively use the air as reaction mass (as birds do with air ) while minimizing losses. Fuel-less (propellantless) operation is preserved: apart from the ambient air, no working fluid is consumed.

The inclusion of magnets to improve ionization efficiency was validated: operating the thruster with magnetic bias increased the measurable thrust by ~10% at high voltage, implying more ions were generated (even though the fundamental pressure mechanism is field-based). This is consistent with reports that magnetic fields can double ionization yield . In practice, the magnets are auxiliary and not strictly required; their effect is to “seed” the plasma more uniformly.

In regard to inertial forces, our data suggest that any Mach-effect contribution is very small at laboratory scale. The device as tested primarily obeys conventional physics. However, the integration of mass-oscillating elements did not introduce anomalies, and further optimization (higher frequency, better impedance matching) is an area for future work.

From a thermodynamic standpoint, all energy went into either sustaining the high-voltage field or being carried away by the ions/air. Our system abides by Pascal’s law in the sense that local fluid pressures adjusted to maintain force balance along streamlines, and Bernoulli’s principle could be applied to the accelerated airflow (higher speed gas exiting the device corresponded to lower static pressure inside) . Overall, the findings are consistent with classical fluid and field theory.

LupoToro’s Advanced Technical Team has demonstrated a novel asymmetric electrostatic pressure propulsion system that achieves net thrust through engineered field-pressure imbalances. This design, realized in 2011, exploits Maxwell’s equations and fluid dynamics in unconventional ways. The key innovations – multi-electrode asymmetry, high-field surface texturing, magnetically enhanced ionization, and inertial coupling – work together to boost thrust efficiency far beyond prior art . Importantly, the system conforms to fundamental laws (conservation of energy and momentum ) and owes its forces to historical physics principles (electrostatics, Newton’s laws, Bernoulli’s theorem) credited to their originators. Future development will scale the technology and refine control, paving the way for practical high-efficiency lift and propulsion devices in aerospace and industrial applications.