High-Energy Laser Weapons: Megawatt-Class Mobile Systems: LupoToro Group Technical Analysis

LupoToro Group’s analysis explores how high-energy laser weapons, capable of delivering megawatt-class precision strikes from compact, container-sized systems, are rapidly redefining modern warfare, as the Group advances its own research in directed-energy technologies for future applications.

In this report, we at LupoToro Group present a comprehensive analysis of high-energy laser (HEL) weapon systems, with a focus on emerging megawatt-class mobile laser platforms. We examine the technological foundations of these directed-energy weapons, their operational characteristics, and the environmental factors influencing performance. Drawing on our internal research and development insights, we break down historical and contemporary laser architectures – from the first ruby lasers to modern fiber and beam-combined systems – and analyze their principles and limitations. We quantitatively assess beam power, intensity on target, optical diffraction constraints, and laser-target interaction thresholds. Furthermore, we evaluate practical battlefield use-cases including counter-drone operations, missile defense, and anti-satellite applications, along with implications for ground and naval warfare. A dedicated section highlights LupoToro Group’s commitment to directed energy innovation, detailing our R&D efforts in beam combining, adaptive optics, power system integration, cooling strategies, and simulation. Throughout this document, we maintain an objective, scientific tone, aiming to inform a technically literate audience (engineers, defense planners, and researchers) with precise data and clear, formal English. The analysis is structured with logical headings, tables, and figures to ensure clarity and ease of reference.

Technological Foundations of High-Energy Laser Systems

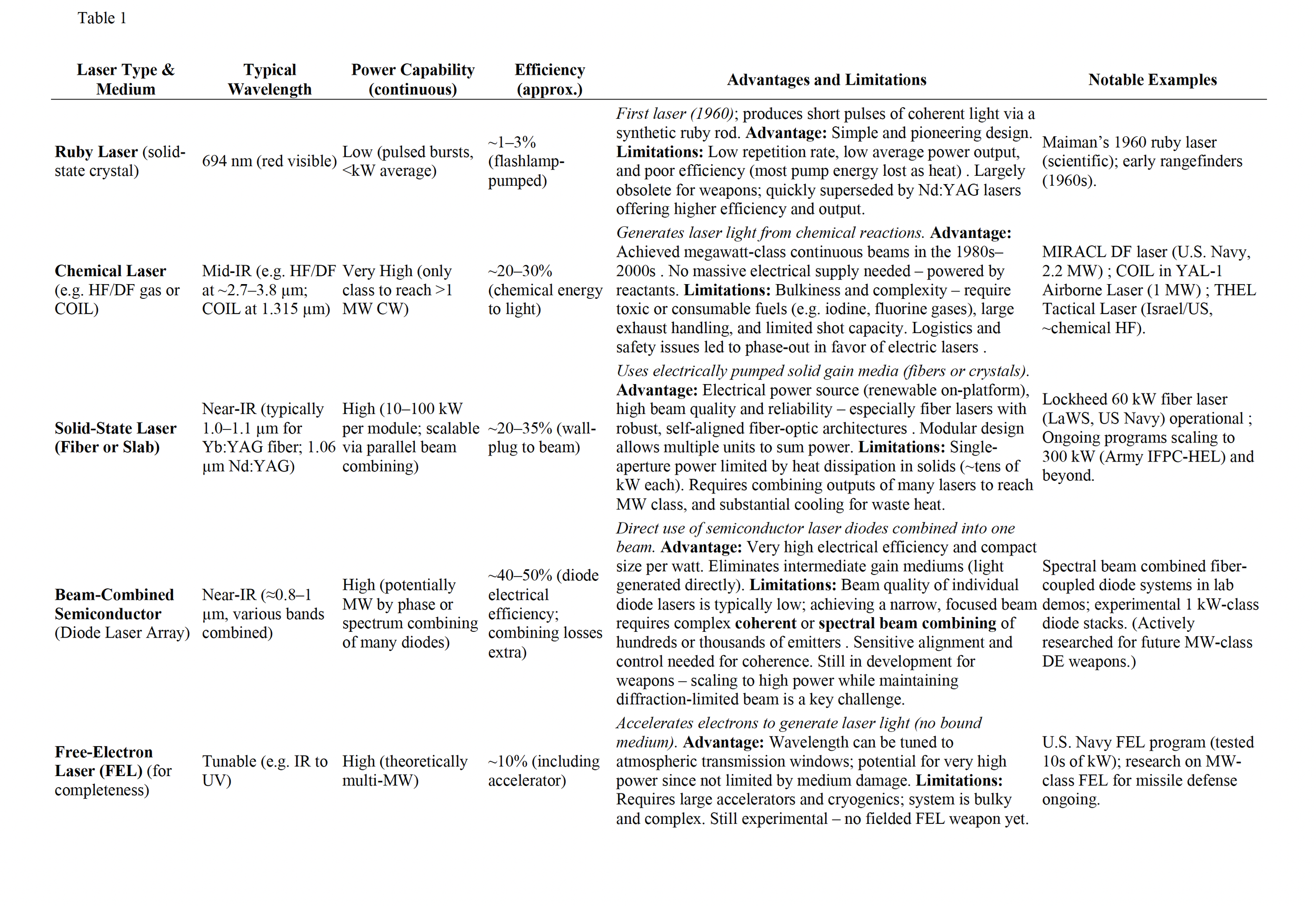

High-energy laser weapons deliver destructive energy to targets at the speed of light by concentrating electromagnetic energy into a coherent beam. To achieve militarily significant effects, a laser weapon must generate a beam with sufficient power (on the order of kilowatts to megawatts), maintain high beam quality (to focus energy on a small spot at long range), and sustain operation through robust power and cooling systems. Over the past six decades, laser technology has evolved through several architectures, each with unique principles and limitations. Table 1 summarizes the major laser types relevant to HEL weapons, including their typical wavelengths, power levels, efficiencies, and operational pros/cons.

Historical Laser Architectures – From Ruby to Gas Dynamics

The first operational laser was the ruby laser in 1960, a solid-state device using a chromium-doped ruby crystal rod as the gain medium. Ruby lasers are pumped by intense flashes of light, producing pulses of deep-red 694 nm light. As a proof of concept, ruby lasers demonstrated the fundamental ability to concentrate optical energy coherently, but they were quickly surpassed for high-power applications . Their low efficiency and inability to sustain high average power (due to heating and limited pumping repetition) made them impractical for weapons. By the mid-1960s, researchers pivoted to alternative media like neodymium-doped glass (Nd:glass) and neodymium:YAG crystals, which offered better efficiency and could be pumped more effectively. These early solid-state lasers achieved kilowatt-level outputs in laboratory settings by the late 1960s , hinting at the potential for laser weapons. However, scaling them further was hampered by waste heat – typically only a few percent of input energy became laser light, with the rest generating heat that distorted the optics .

Recognizing these limitations, attention turned to gas lasers and other concepts. CO2 gas lasers (10.6 µm wavelength) and gas-dynamic lasers were explored; by 1970 a gas-dynamic CO2 laser had produced a continuous 60 kW beam . This was an important milestone: it proved that continuous-wave high-energy beams were feasible. Yet, CO2 lasers operate in the long-wave infrared (~10 µm) where atmospheric absorption is significant, and their efficiency remained modest. The quest for battlefield-ready lasers led to a new approach in the 1970s: chemical lasers.

Chemical High-Energy Lasers – Megawatt-Class Pioneers

Chemical lasers harness the energy of chemical reactions to directly excite the laser medium, achieving far greater power than early electrical lasers. A classic example is the Hydrogen Fluoride (HF) or Deuterium Fluoride (DF) laser, where reactive chemicals (typically mixing hydrogen or deuterium gas with fluorine) produce excited HF/DF molecules that emit laser light in the mid-infrared. Another prominent type is the Chemical Oxygen-Iodine Laser (COIL), which uses a reaction of chlorine and hydrogen peroxide to create excited oxygen molecules that then excite iodine atoms to lase at 1.315 µm. These lasers can operate in continuous-wave mode with outputs reaching into the megawatt range – a feat unattainable by other laser types until recently. In fact, for many years chemical lasers were the only class of HEL to achieve megawatt-class continuous beams .

Several major defense projects in the late 20th century showcased chemical laser technology:

The U.S. Navy’s MIRACL (Mid-Infrared Advanced Chemical Laser), a DF laser, produced a beam over 1 MW and remains one of the highest-power continuous lasers ever demonstrated . It was test-fired against targets like missiles and satellites in the 1980s and 90s.

The joint U.S.-Israeli Tactical High Energy Laser (THEL) used a deuterium fluoride laser to shoot down Katyusha rockets and artillery shells in tests (circa 2000). It proved a laser could neutralize short-range threats but was a large, static ground-based system.

The U.S. Air Force’s Airborne Laser (ABL) program in the 2000s equipped a Boeing 747-400F (designated YAL-1A) with a megawatt-class COIL laser to intercept ballistic missiles during boost phase . This system, with a 1.6 m diameter beam-director telescope in the nose, successfully shot down test missiles in 2010

Chemical lasers offered unprecedented power, but their drawbacks became apparent. They required carrying hazardous chemical fuel and oxidizers, yielding corrosive exhausts that had to be managed. The systems were enormous – for instance, the ABL’s laser occupied most of the 747’s fuselage, along with tanks for chemicals and complex plumbing. Each shot of the laser consumed finite reagent supplies; in the ABL design, one sortie’s worth of chemicals was intended to destroy 20–40 missiles . While effective in tests, these lasers were essentially “one-shot” or limited-shot weaponsbefore needing refurbishment of reactants. Moreover, the logistical burden and safety risks (handling toxic gases like fluorine) made field deployment challenging outside of controlled environments.

By 2010, the U.S. Department of Defense pivoted away from chemical lasers, seeking “renewable” electrically-powered lasers that rely on a vehicle’s power generator rather than consumable fuel . Chemical laser programs like the ABL were terminated by 2012 . The legacy of chemical HELs, however, is significant – they proved that destroying missiles and other targets with directed energy is feasible, and they provided a wealth of data on beam propagation at high power. Lessons from these systems (e.g., the need for atmospheric compensation and beam control, discussed later) directly informed the development of the next generation of solid-state lasers.

Solid-State Lasers – Fiber Optics and Advanced Solid Media

Solid-state lasers use a solid gain material (such as a doped crystal or optical fiber) energized by an external source (usually flashlamps or laser diodes) to produce laser light. Early solid-state HEL efforts (like Nd:YAG or Nd:glass lasers) were limited by low efficiency and thermal distortion at high power. However, diode-pumped solid-state lasersrevolutionized the field. In these, semiconductor diodes efficiently convert electricity to light which pumps the solid gain medium, drastically improving efficiency and thermal management compared to old flashlamps.

One particularly promising variant is the fiber laser. In a fiber laser, the gain medium is a flexible optical fiber (often Yb:YAG-doped silica) guided within a fiber waveguide. Pump diodes inject light into the fiber, and laser emission emerges as a high-quality, diffraction-limited beam. Fiber lasers combine several advantages critical for military use:

Efficiency and Power Scaling: Modern fiber lasers can achieve wall-plug efficiencies on the order of 25–35% , meaning a large fraction of electrical input becomes laser output (significantly reducing waste heat). Multiple fibers can be “spliced” or combined to scale power; e.g., bundles of 25–50 fiber amplifiers have produced >50 kW output while maintaining beam quality .

Beam Quality: The waveguide nature of fibers helps maintain single-mode operation. Fiber lasers naturally produce a high-quality beam that can be tightly focused at long range. Beam combining of many fiber lasers is possible either incoherently (simply overlapping beams) or coherently (phasing them), with the latter offering near-diffraction-limited performance if done correctly .

Ruggedness: The fiber architecture is inherently robust; many optical functions (wavelength multiplexing, splitting, isolation) can be integrated into fiber components, reducing the need for delicate free-space optics . This robustness is important for mobile applications subject to vibrations and harsh conditions.

Modularity: A fiber laser weapon can be built by ganging together modular laser units (10 kW-class fiber amplifiers, for example). This offers redundancy and graceful degradation – if one module fails, the others still function, and maintenance can be modular.

In recent years, fiber laser weapons have transitioned from prototype to operational testing. Notably, the U.S. Navy deployed a 30 kW fiber laser (LaWS) on USS Ponce for trials in 2014, successfully disabling UAVs and small boats. Since then, 50–100 kW class systems have been developed for Army and Navy use. For instance, a 60 kW Lockheed Martin fiber laser was delivered for Navy testing , and a 100 kW-class laser (HELMTT and subsequent programs) for the Army proved capable of shooting down drones and artillery rounds. Within the next 5 years, 300 kW solid-state lasersare expected to be deployed on ships and trucks, providing a significant increase in lethality against faster targets like missiles.

It is worth noting that slab lasers (solid rectangular crystal amplifiers) also contributed to HEL development (e.g., the 150 kW DARPA HELLADS used liquid-cooled slabs). Slab systems can achieve high power but face challenges with thermal lensing and beam distortion. Fiber lasers have largely overtaken slabs due to their superior beam quality and easier thermal management.

As of 2025, fiber laser technology is on the cusp of the megawatt threshold. Defense roadmaps have anticipated that “50–100 kW militarized devices” would be achieved by the mid-2020s and that “megawatt (MW) systems [could be] available within 20 to 30 years” of those early predictions . Indeed, we now have 100+ kW prototypes and are imagining scaling to 1 MW by the 2030s via combining tens or hundreds of fiber amplifiers. Our internal assessments at LupoToro align with this: continued maturation of fiber laser materials, diode pumps, and thermal control is expected to make mobile MW-class electric lasers a reality in the foreseeable future.

Beam-Combined Semiconductor Lasers – Direct Diode Power

Another cutting-edge architecture is the use of direct semiconductor lasers as the source of high-power beams. Semiconductor laser diodes are extremely efficient at converting electricity to light (often >50% efficient) and can be manufactured in large numbers. However, a single diode laser has a low beam quality (divergent output) and relatively low power (watts to tens of watts per emitter). To use them in a weapon, many diode outputs must be combined into one coherent beam.

Techniques for beam combining include:

Spectral Beam Combining (SBC): Diodes of slightly different wavelength are combined with prism or grating optics into one beam. Since the wavelengths differ, they don’t interfere, and the combined beam can carry the sum of all power. SBC has been demonstrated to combine on the order of 10–100 kW of diode arrays.

Coherent Beam Combining (CBC): Diode outputs (or fiber lasers) are phase-locked with each other so that they add in phase at the target, effectively acting like a single larger laser. CBC is more complex, requiring feedback loops to align phases. It promises near-ideal beam quality if achieved. Recent experiments have coherently combined on the order of 10–20 lasers, and efforts continue to reach 100+ way combinations .

The appeal of direct diodes is the simplicity: skip the intermediate gain medium (like fiber or crystal) and go straight from electricity to a high-power beam. In practice, current high-energy laser systems often use diode lasers indirectly – for example, pumping fiber lasers. But in the future, diode laser arrays could be scaled up more directly. Experimental systems have shown 100 kW-class diode laser combined outputs, though beam quality is still under active research and usually not as good as fiber lasers unless using advanced CBC.

The technological landscape of HELs has shifted from chemically powered behemoths to more compact, electrically-driven lasers. Each architecture – solid-state, fiber, diode, etc. – comes with trade-offs in efficiency, complexity, and scalability. For truly mobile, field-deployable megawatt-class lasers, the current consensus (which we share at LupoToro Group) is that combining many high-quality electric lasers (fiber or diode-based) is the most viable path. The following sections analyze how such high-power beams propagate and what challenges must be overcome for effective operation in real-world environments.

Operational Characteristics of Megawatt-Class Laser Platforms

Designing a mobile megawatt-class laser weapon requires more than just the laser device itself. It entails an integrated weapon system including beam generation, beam control (steering and focusing), targeting sensors, power supply, and thermal management – all configured on a platform such as a vehicle, ship, or aircraft. Here we outline the key operational characteristics and considerations for deploying such systems.

Engagement Timeline and Speed-of-Light Delivery: One of the greatest operational advantages of lasers is that they deliver energy to the target virtually instantaneously (at the speed of light). In practice, an engagement sequence for a laser weapon involves: detecting and tracking a target (using radar or electro-optical sensors), aiming the beam director (turret) at the target, perhaps using a low-power illuminator laser to precisely track and measure atmospheric distortion, and then firing the high-power laser to strike the target. The energy deposition on the target can be precisely controlled – scaled from non-lethal dazzling to destructive levels – by adjusting the dwell time and power. We emphasize that time on target is a critical parameter: unlike a bullet or fragment that delivers kinetic energy in a fraction of a second, a laser may need to dwell on the same spot for a few seconds to inflict sufficient damage (depending on target hardness). Thus, while the beam arrives immediately, the weapon must maintain line-of-sight and track the target during the engagement.

Precision Targeting and Beam Steering: High-energy lasers are inherently line-of-sight weapons. They travel in a straight line (unless redirected by mirrors), and thus the platform must have a clear path to the target – no hiding behind hills or thick clouds. The pointing accuracy required is extremely high: at long ranges (tens of kilometers), a 0.1 mrad pointing error could miss the aim point by meters. Therefore, laser systems use advanced pointing and tracking assemblies, often leveraging stabilized gimbals, fast steering mirrors, and feedback from tracking sensors. For example, the ABL’s beam control system included a fine tracking laser and a beacon laser that measured atmospheric turbulence, feeding data to an adaptive optics system . A deformable mirror in the beam path could adjust its shape 1,000 times per second to counteract wavefront distortions , ensuring the high-power beam stayed tightly focused on the target. This kind of integration between optics and control systems is essential for long-range, high-power laser engagements.

Mobility and Platform Integration: A megawatt-class laser can, in theory, be deployed on various platforms:

Airborne platforms: like the YAL-1A 747 or smaller planes. High altitude airborne lasers have the advantage of reduced atmospheric interference (above much of the weather and dense air) and extended line-of-sight. However, aircraft face weight and space limits; the ABL’s experience (filling a jumbo jet) showed that chemical lasers push those limits. Future electric lasers might be more compact; for instance, a 150 kW laser was envisioned for a C-130 gunship (ATL program) , and smaller UAVs might carry tens of kW for self-defense. Still, integrating a MW-class electric laser would likely require a large aircraft or next-generation airborne platform due to the power supply and cooling demands.

Ground vehicles: The Army and other forces are testing truck-mounted lasers (50–300 kW range currently). A megawatt laser on a ground vehicle would be a significant challenge because 1 MW of output might require ~2–3 MW of input power (taking into account inefficiency and cooling). This is roughly equivalent to the engine power of a main battle tank. A notional mobile MW laser might be a multi-vehicle system: one vehicle carrying the laser and optics, and additional vehicles carrying power generators, battery banks, or cooling units. The Army Mobile Tactical High Energy Laser (MTHEL) concept in the 2000s was such a system (though chemical, it required multiple support trucks) . Any mobile HEL must also handle vibrations, dust, and shocks – requiring ruggedized optics and auto-alignment systems.

Naval platforms: Warships are attractive platforms for HELs because they have substantial power generation capacity (especially ships with integrated electric propulsion or onboard nuclear reactors) and ample space for cooling equipment. The U.S. Navy is actively integrating lasers in the 60–300 kW class on destroyers and plans for higher power in the future. A megawatt-class laser could potentially be mounted on a large ship or a dedicated vessel. The benefit at sea is clear air over water (on clear days) and the ability to handle heavy equipment; the challenge is maritime environment (salt spray, motion, etc.) which demands sealed and stabilized systems.

Field of Regard and Beam Director: Unlike a fixed gun, a laser’s “barrel” is essentially a mirror turret that must swivel to aim. Many designs use a dome or turret with a window through which the laser exits. For instance, the ABL’s nose turret had a ±120° azimuth field of regard . Ground or ship lasers often use a rotating turret that can cover 360° in azimuth and a wide range in elevation (from horizon to near-zenith). These turrets must keep the beam director optics very stable and precisely pointed, often with the help of fast steering mirrors for fine jitter control. The complexity is akin to a precision telescope tracking a fast-moving object, complicated by the need to also compensate for platform motion (vehicle rocking, ship roll, etc.).

Operating a megawatt-class laser in the field is a coordinated ballet of high-tech subsystems: powerful lasers, exquisite optics, and advanced control systems all working in unison. Our approach at LupoToro Group has been to treat the HEL weapon as a holistic system – not just a laser, but an integration of sensors, algorithms, and hardware that must be engineered together. The next sections delve into two crucial aspects of this integration: the propagation of the beam through the atmosphere, and the performance metrics of the beam on target.

Atmospheric Propagation and Environmental Limitations

A defining challenge for high-energy lasers is that they must propagate through the Earth’s atmosphere to reach their targets. Unlike the vacuum of space, the atmosphere introduces several deleterious effects that can attenuate, scatter, or distort a laser beam. Here we discuss these environmental limitations and some strategies to mitigate them, including adaptive optics. Understanding these factors is vital – a megawatt laser is only effective if a sufficient fraction of its energy actually deposits on the target, rather than being lost in transit.

Absorption: Certain gases in the air (such as water vapor, carbon dioxide, oxygen) can absorb laser light at specific wavelengths. This converts some of the beam’s energy into heat in the air rather than delivering it to the target. The degree of absorption depends strongly on the laser wavelength. The atmosphere has “transmission windows” – bands of wavelength where absorption is relatively low – interspersed with bands of high absorption. For example, near-infrared wavelengths around ~1.0–1.2 µm, ~1.6 µm, and ~2.2 µm offer low atmospheric absorption (hence are preferred for long-distance propagation) . Indeed, it is no coincidence that many HEL systems operate near 1 micron (Yb fiber ~1.06 µm or Nd:YAG 1.064 µm, or COIL 1.315 µm) which lies in a favorable window. By contrast, a HF/DF chemical laser emitting around 3.6–3.8 µm experiences stronger absorption due to atmospheric moisture. Longer wavelengths like the CO2 laser at 10.6 µm have a well-known “infrared window” between ~8–12 µm where transmission is moderate, but still worse than the near-IR window. Atmospheric absorption effectively limits the range of a laser for a given power – beyond a certain distance, the beam may be so attenuated that it can no longer achieve damage on target. This range depends on humidity, air density, and wavelength. In practice, choosing a wavelength in an atmospheric window and possibly tuning the wavelength slightly (if using a tunable laser like FEL) can minimize absorption losses.

Scattering: Particulates and aerosols in the air (dust, smoke, fog droplets) scatter laser light out of the beam path. Scattering can be Rayleigh scattering off air molecules (significant for shorter wavelengths, e.g. blue lasers scatter more than IR) or Mie scattering off larger particles (like mist or dust, which can affect even IR beams). Scattering not only reduces beam intensity but can also make the beam visible (the classic “Star Wars beam” effect is due to light scattering towards an observer’s eye). For HEL weapons, scattering is especially problematic in bad weather. Fog, clouds, or rain can severely diminish laser effectiveness, potentially reducing the effective range to almost nothing. For instance, a moderate fog (visibility a few hundred meters) can absorb/scatter the vast majority of a laser’s energy in that distance. Even clear air has some molecular scattering, but under clear, dry conditions at sea level, the losses are modest for IR wavelengths. Higher altitudes have less scattering (fewer particles, less dense air), which is why airborne lasers gained interest – at 40,000 feet, above the clouds, a beam can propagate much farther

To quantify, extinction (the combination of absorption + scattering) is often expressed as a per-kilometer attenuation factor. A high-energy laser needs to deliver a certain intensity (W/cm²) on target; heavy haze or dust could impose an exponential attenuation that makes long-range shots impractical. In our simulations at LupoToro, we find that even a 1 MW laser could be reduced to kilowatts at the target if it must traverse a kilometer of dense fog. Thus, weather constraints are a major operational consideration – HEL systems will have degraded performance in battlefield obscurants (smoke screens, dust storms) or poor weather. They are not all-weather weapons, unlike some kinetic weapons that can penetrate clouds or operate via radar. This limitation drives interest in pairing lasers with other systems or developing tactics to mitigate environmental factors (e.g. locating laser platforms in arid regions or above the weather, such as high-altitude UAVs or stratospheric airships).

Thermal Blooming: A unique effect at high beam powers is that the laser can heat the air it passes through, causing the air to actually defocus or deflect the beam. This is called thermal blooming. As the beam deposits heat in the air (via absorption or even just residual atmospheric molecules), the local air temperature rises, causing a change in refractive index (hot air is less dense). The hotter column of air acts like a lens that tends to spread the beam out (“blooming” it like a flower). Thermal blooming is exacerbated by high-power, continuous-wave beams in lower atmosphere, especially on humid days (since heating moisture in air has large effects). It becomes a self-limiting phenomenon: the more you crank up the laser power, the more the beam wants to defocus itself due to heating the medium it’s traveling through.

Engineers can mitigate thermal blooming by a few methods:

Shorter engagement range or altitude: Blooming effects accumulate with distance. Engaging at closer range lessens the path length for blooming to distort the beam. The ABL flying at high altitude reduced the air density (and thus blooming).

Beam shaping: Intentionally enlarging the beam diameter through the near-field can reduce intensity in the air, so less heating occurs. The beam can then be refocused near the target. For example, a laser might use a slightly defocused beam to transit the first kilometers, then rely on a focusing lens to concentrate right before the target. Care must be taken as defocusing also lowers intensity on target.

Pulsed or dithered firing: Using high peak power pulses with low duty cycle can let the air cool between pulses, avoiding continuous heating. Ultra-short pulses (femtosecond lasers) are an extreme case – they deposit energy so quickly that blooming during the pulse is negligible, though their average power is low. As noted in one study, ultra-short pulses can propagate without normal diffraction spreading under certain conditions , but those are not yet at high average power for weapon use.

Wavelength selection: If a wavelength has less absorption, it will deposit less heat in the air (e.g. 1.06 µm vs 3.8 µm, the latter heats air more). So again, the 1 µm band is advantageous.

In designing our beam propagation models, LupoToro Group pays particular attention to thermal blooming as a key factor limiting effective range at full power. Adaptive optics (discussed next) can also help compensate for some blooming by adjusting the wavefront as it changes.

Atmospheric Turbulence (“Seeing” and Beam Wander): The atmosphere is turbulent, with cells of air at different temperatures and densities moving around. This causes random fluctuations in refractive index along the beam path – the same reason stars appear to twinkle to the naked eye. For a laser beam, turbulence causes the beam to wander, break into speckle patterns, or broaden. The effect is called scintillation. Over long distances, turbulence can create multiple patches of intensity (speckle) at the target instead of one coherent spot, reducing peak intensity. It can also cause rapid jitter of the beam’s aim point.

Adaptive Optics (AO) is the primary tool to combat turbulence. By using a wavefront sensor (e.g., a Shack-Hartmann sensor) that looks at a reference beam or a return reflection, the system measures the distortion pattern of the wavefront. A deformable mirror (a mirror with many tiny actuators) then distorts in the opposite way, canceling out the aberration. The result is a beam that, after passing through the turbulent atmosphere, arrives much closer to planar (in phase) at the target. In the ABL tests, the AO system proved crucial to keep the beam tightly focused on a missile at 100+ km; without it, turbulence would have enlarged the spot and reduced effectiveness drastically .

Modern ground lasers also use adaptive optics, though implementing AO on fast-moving small targets (like drones) is challenging – there might not be a convenient “guide star” or time to close the loop. One approach is to use a low-power beacon laser that reflects off the target or back-scatter from the path, as was done in the ABL with a Beacon Illuminator Laser . Another approach is predictive control: using sensors and algorithms (potentially AI-based, as some research suggests ) to anticipate and correct beam pointing ahead of time for a maneuvering target through turbulence.

Visibility and Signature: As a side note, a high-power laser beam, especially in scattering conditions, may be visible to observers (a glowing lance of light) . This is generally not a tactical concern in active combat (the laser is likely a giveaway when it fires due to its effects), but for covert or peacetime operations, some wavelengths (IR) are less visible than others. A 1 µm near-IR beam is just on the edge of human vision (a faint red glow if scattering occurs); a 532 nm green laser (as sometimes used in tests after frequency-doubling a YAG) is very visible. During many tests, a visible tracking laser is used for alignment, which can create dramatic photographs. In actual operations, HEL weapons would likely use wavelengths invisible to the naked eye to avoid giving a visual cue. There is also a safety consideration: even scattered laser light can be hazardous to eyes at surprisingly long distances, which implies rules for laser use in training and conflict (deconflicting airspace, etc., so as not to inadvertently blind friendly sensors or pilots).

the atmosphere is the dominant factor in determining the effective range and reliability of HEL systems. Clear skies and dry air can allow a high-power laser to reach targets hundreds of kilometers away (as envisioned in some strategic scenarios) , whereas rain, fog, or dust can reduce the range to virtually zero. At LupoToro Group, our simulations incorporate atmospheric models (for absorption, scattering, and turbulence) to predict laser performance under various environmental conditions. We also work on techniques like adaptive optics and novel beam control algorithms to maximize energy on target despite atmospheric disturbances. Field testing of our lasers includes operation at different times of day and weather conditions to empirically validate these models. Ultimately, while we can mitigate many atmospheric effects, a commander employing HEL weapons must understand these constraints – in essence, lasers are powerful but demand favorable conditions or proper compensation techniques to be fully effective.

Performance Metrics and Laser-Target Interaction

To appreciate the destructive potential and limitations of high-energy lasers, it is essential to discuss key performance metrics quantitatively. In this section, we examine beam power and intensity, focusing ability (diffraction and spot size), and the energy required to damage or destroy targets. We introduce representative formulas and threshold values that govern laser-target interactions.

Beam Power and Intensity: The primary metric of a laser weapon is its output power, typically expressed in kilowatts (kW) or megawatts (MW) for HEL systems. However, raw power alone does not determine effectiveness – what matters is the intensity (irradiance) delivered to the target, measured in watts per square centimeter (W/cm²). Intensity is what drives heating, melting, or ablating of target materials. A high-power laser spread over a large spot may do little damage, whereas a lower-power laser tightly focused to a small spot can achieve the required intensity to burn through a material.

The intensity $I$ on target can be approximated by the formula [ I \approx \frac{P}{A_{\text{spot}}} = \frac{4P}{\pi d^2} ], where $P$ is the laser power and $d$ is the full spot diameter on the target (assuming a roughly circular spot). For example, a 1 MW laser focused to a 10 cm diameter spot has area $A \approx 78.5~\text{cm}^2$, yielding an average intensity on the order of $1{,}000,000~\text{W} / 78.5~\text{cm}^2 \approx 12,740~\text{W/cm}^2$ (12.7 kW/cm²). Such an intensity would rapidly melt or vaporize many materials. But if that same 1 MW beam were defocused to a 1 m spot (10,000 cm²), the intensity would drop to ~100 W/cm², likely insufficient to do more than warm the target.

Thus, achieving a small spot size at the target is just as important as generating high power. This brings us to the issue of diffraction and beam divergence.

Diffraction and Spot Size: No matter how perfect the optics, any finite-aperture laser beam will diverge due to diffraction. For a circular aperture of diameter $D$ emitting a beam of wavelength $\lambda$, the minimum angular divergence (half-angle) $\theta_{\text{diff}}$ for a diffraction-limited beam is approximately: \theta_{\text{diff}} \approx 1.22 \, \frac{\lambda}{D} ,

where $\theta$ is in radians . This formula stems from the Rayleigh criterion for the Airy diffraction pattern. The spot diameter at a range $R$ (to first null of the Airy disk) would be about $2 \cdot 1.22 \frac{\lambda}{D} R \approx 2.44 \frac{\lambda R}{D}$. A rule of thumb often cited is spot size (diameter) $\approx \frac{2\lambda R}{D}$ for long distances, which is in the same ballpark.

What this means practically: for a given wavelength, a larger aperture (bigger mirror) yields a tighter focus (smaller far-field spot). Or conversely, for a fixed aperture, shorter wavelengths diverge less.

Let’s plug in some numbers. Suppose we have a 1 m diameter beam director (as in the ABL’s system, $D\approx1.5–1.8$ m, but we use 1 m for easy math) and a $\lambda = 1.064~\mu$m (Nd:YAG or Yb fiber) laser. The diffraction-limited divergence half-angle is $\sim1.22 \times 1.064\times10^{-6} / 1 = 1.3\times10^{-6}$ radians (which is ~0.26 microradians half-angle). At R = 100 km, the central spot radius would be $\theta R \approx 0.13$ m (13 cm), so a full spot diameter of ~26 cm. At R = 10 km, the diffraction spot might be ~2.6 cm across. These are remarkably small spots for such ranges – indicating that, if one can maintain near-diffraction-limited performance, a high-power laser can concentrate enormous intensity even at tens of kilometers.

In reality, various imperfections and atmospheric effects usually cause the beam to diverge more than the diffraction limit (often characterized by a “beam quality factor” $M^2$ > 1). Nevertheless, designing HEL systems with large-aperture beam directors and short wavelengths is crucial for long-range effectiveness . For example, the decision to use chemical oxygen-iodine (1.315 µm) in the ABL instead of HF (3.8 µm) was influenced by the much lower diffraction and better focusability at 1.3 µm .

Now, consider a scenario from one of our analyses (similar to published studies): A 1 MW, 532 nm (frequency-doubled green) laser with a 1 m mirror and adaptive optics to correct turbulence. At 200 km, it could focus to roughly a 20 cm spot (about 1.5× the diffraction limit) . The intensity in that spot would be on the order of $3.2~\text{kW/cm}^2$ . This is extremely high: 3.2 kW/cm² can perforate metal. Indeed, calculations show such a beam could burn through ~6 mm of aluminum per second even at 200 km . At closer ranges like 50 km, the spot might tighten to ~5 cm diameter, raising intensity and drilling through >8 cm of aluminum per second – essentially cutting even thick structures almost instantaneously. While this example is somewhat idealized (532 nm is visible light and more subject to atmospheric scatter, and holding an exact 20 cm spot at 200 km is very challenging), it illustrates the incredible potential of combining high power and excellent beam quality.

Laser-Target Interaction Thresholds: To damage a target, the laser must deliver enough energy (or power over time) to exceed certain thresholds:

Soft-kill vs Hard-kill: A “soft kill” might involve dazzling sensors or overheating electronics, which can require relatively lower energy (perhaps $\sim10^2–10^3~\text{J/cm}^2$ delivered). A “hard kill” (structural damage, explosion of ordnance, etc.) usually needs more energy to melt or rupture materials.

Material properties: Different materials have different melting points, thermal conductivities, and specific heats. For instance, aluminum (common in aircraft and some missiles) melts at ~660 °C and is relatively thermally conductive, whereas steel melts at ~1400 °C. To burn through a thin skin, one needs to deposit enough energy to raise a spot of that material to the melting/vaporization point faster than heat diffuses away.

Typical required fluence: A commonly referenced metric is that many unarmored targets (drones, missile skins, thin metal) might have a “hardness” on the order of 1–10 kJ/cm² . That is, if you deposit ~1,000 to 10,000 Joules of energy per cm² on the target, you will cause severe damage or penetration. If a laser delivers, say, 5 kW/cm² on target, it would take about 0.2 seconds to deliver 1 kJ/cm², or 2 seconds to deliver 10 kJ/cm², at that spot. In fact, one analysis using 1–10 kJ/cm² as a bracket estimated dwell times of order 0.3–3 seconds at 50 km for a 1 MW laser, and shorter as range decreases . Those dwell times are quite practical for an HEL weapon (holding a beam for a second or two on a non-maneuvering missile is feasible with good tracking).

We can illustrate with a specific case: A typical small UAV might have a plastic or composite airframe that ignites or fails at relatively low energy – perhaps a few hundred J/cm² might be enough to set fire to a wing. This is why even a 10 kW laser can down drones within a couple kilometers: the laser can keep a beam on the drone for a few seconds and deposit that energy. On the other hand, a ballistic missile’s metal body might need a couple thousand J/cm² to burn through, but if it’s carrying fuel under pressure, even a small breach can cause it to explode. This was the rationale of the ABL: deliver on the order of 10 kJ/cm² to a boosting missile’s skin to cause a failure . The ABL achieved this in tests at tens of kilometers (though operationally it needed to be within a few hundred kilometers of the launch site, which was a strategic limitation).

Optical Diffraction Limit vs. Target Size: Another consideration is if the target is much larger than the beam spot or not. For small targets like mortar shells or very distant missiles, the spot size might be comparable to the target size (e.g., a 0.2 m spot on a 0.5 m diameter shell). In such cases, precise aim is needed to hit a vulnerable point (like the warhead or a critical component). For larger targets (drones, aircraft), a small spot just needs to be held on a critical area (fuel tank, control surfaces, sensor) to achieve the effect.

Multiplexing and Multi-Target Engagement: Lasers currently engage one target at a time, but high power allows quick sequential shots. For example, a 100 kW laser that takes 5 seconds to disable one UAV can, in theory, engage 12 targets per minute if retargeting is instantaneous. Some new systems, like the Australian 150 kW “Apollo” laser, claim the ability to slew fast enough and with sufficient power storage to take out 20 drones per minute (3 seconds per drone on average). They achieved this by designing high-speed beam directors (60° coverage in 0.7 seconds) and perhaps using burst power from an internal battery to get short surges of >100 kW on each target . The internal power storage allowed Apollo to supposedly shoot down up to 200 drones before recharging . This highlights how power and target interactiontie into system design: the laser must have not only raw power but also the ability to store or generate energy for repeated engagements and to swing quickly between targets. It also underscores that as laser weapons move to higher power (hundreds of kW to MW), the engagement time per target drops, enabling a single laser to counter swarms or salvos more effectively.

The performance of a high-energy laser system can be boiled down to delivering sufficient intensity for sufficient time on target. The quantitative tools – diffraction formulas, energy fluence thresholds, etc. – allow us to predict outcomes: for instance, will a given laser shoot down an incoming missile in the 5–10 seconds available during its flight? We apply these calculations in our design evaluations at LupoToro. If the numbers don’t meet the threshold (say we only get 0.5 kJ/cm² on the target when 5 kJ/cm² is needed), we know the system either needs more power, a larger aperture, or is simply not viable for that scenario without dramatic changes. It is this quantitative rigor that turns directed-energy concepts into practical weapon designs.

Battlefield Applications and Use Cases

High-energy lasers offer unique capabilities across a range of military domains. Here we assess several key use cases for HEL systems – from countering drones to strategic missile defense – and consider the benefits and limitations in each context.

Counter-Unmanned Aerial Systems (C-UAS): The proliferation of drones (UAVs) – from small quadcopters to larger reconnaissance drones – has driven a surge in laser weapon development for short-range defense. Lasers are well-suited to this mission: drones are typically fragile, line-of-sight targets. Even a 10–50 kW laser can engage small drones at distances of 1–3 km, silently and with precision. For example, Israel’s Iron Beam system (about 10 kW) has reportedly shot down drones and mortars at a few kilometers range . A 100 kW-class laser can neutralize drones even faster and at greater distances; one NATO trial with a 100 kW laser demonstrated disabling multipledrones in rapid succession . The advantages here are clear: virtually zero cost-per-shot (just electricity), and an inexhaustible “magazine” as long as power is available – critical when faced with a swarm of dozens of cheap drones. HELs also minimize collateral damage; they can destroy the drone in the air without explosive warheads. The limitations include weather (as always) – lasers may struggle in rain or low clouds exactly when drones might fly low – and the possibility of drones using countermeasures like reflective coatings or fast evasive maneuvers. However, practical countermeasures to high-power lasers are not trivial; a mirror-like coating might reflect some energy but is unlikely to survive kilowatts of heating for long (and tends to add weight to the drone) . Overall, C-UAS is considered the first niche where lasers will see regular operational use, given the current success of prototypes and the pressing threat of drone swarms.

Short-Range Air Defense (Missiles & Rockets): Lasers are being integrated into point defense systems to intercept rockets, artillery, mortars (RAM), and short-range missiles (like anti-ship cruise missiles or anti-tank guided missiles). For example, the THEL testbed in the late 90s showed a chemical laser could shoot down artillery rockets in flight. Today, the U.S. Army is testing lasers in the 50–300 kW range for its Indirect Fire Protection Capability (IFPC-HEL) to defeat incoming rockets and cruise missiles. The benefit is that a laser, with its speed-of-light targeting, can potentially engage projectiles very soon after detection, and potentially handle multiple sequential shots if more threats are incoming. A laser also avoids the risk of unexploded interceptors falling to ground, etc., since it’s a pure energy beam. However, the challenge is time on target – a mortar shell or rocket might only be in the air for 10–20 seconds, and the laser may have only a few seconds of engagement window at best (depending on detection and tracking latency). The laser must deposit enough energy in that short time to either detonate the warhead or structurally destroy the threat. For high-power lasers, this is achievable at short range: e.g., a 100 kW laser at a kilometer or two might burn through a metal casing in a second or less. As power scales up, the lethal range extends. Another aspect is missile defense: lasers have been considered for boost-phase intercept of ballistic missiles (as with the ABL), which is a demanding mission requiring megawatt power and long range. The ABL’s concept was to station a laser aircraft near hostile territory and shoot down missiles during ascent, when they are slow and have big bright plumes for tracking . It did shoot down test missiles at a range of on the order of 100 km , but practical use was limited by the aircraft needing to be within perhaps 200 km of the launch point (dangerous in a contested area). Ground-based or ship-based lasers for missile defense would face even more atmospheric challenges for long distances. Going forward, some concepts envision a network of high-altitude drones or airships with lasers, or space-based lasers, to tackle ballistic missiles – but those are future, strategic applications that come with significant cost and policy implications.

Anti-Satellite (ASAT) and Space Assets: Lasers can be used to dazzle or damage satellites. Even relatively low-power (tens of kW) lasers can saturate or blind the sensitive optical sensors on reconnaissance or spy satellites if accurately pointed. Indeed, there have been reports of terrestrial lasers used to dazzle imaging satellites, essentially overexposing their sensors to prevent data collection (this is a reversible, non-destructive effect if done at low power). For destructive ASAT action, a very high-power laser could theoretically damage satellite structures or subsystems. The advantage of lasers for ASAT is they reach the target almost immediately and can be precisely targeted without debris generation (if just dazzling). However, to physically destroy or disable a satellite in orbit (hundreds of km up) would likely require a megawatt-class laser and a large aperture, perhaps on a mountain or airborne to reduce atmospheric traversal. The ABL was speculated to have an ASAT capability against low-orbit satellites if it flew under their path ; the thinner upper atmosphere would let more beam energy through, and satellites have vulnerable optical components and solar panels that could be fried . This application is highly sensitive politically (ASAT weapons can spark space debris issues and escalation), so currently lasers are more discussed in the context of temporary dazzling or enforcing “no-fly” zones for adversary satellites during conflicts. Nonetheless, as part of a multilayer defense, HELs could play a role in counter-space operations.

Naval and Ground Targets: On the ground and at sea, lasers provide some unique engagement options. For naval ships, one near-term role is complementing or replacing the Close-In Weapon System (CIWS) guns to shoot down incoming anti-ship missiles or drones. A 150 kW laser on a ship, for instance, could attempt to heat the seeker or control surfaces of an incoming missile at a few kilometers, potentially causing it to fail. The Navy’s goal is to field lasers that can handle small boat swarms, UAVs, and supersonic anti-ship missiles as an added layer of defense. The advantages include a virtually endless magazine (important for ships on long patrols) and reduced logistics of ammunition. Also, lasers have a huge engagement speed advantage – a maneuvering fast boat can’t dodge a laser like it could a slower projectile. The limitations are that heavy sea haze, mist, or rain can curtail range significantly, and that current laser power (100–300 kW) might be marginal to quickly kill a supersonic missile unless at relatively close range (under 2 km). However, even if the laser cannot fully destroy a missile, it might blind its seeker or scorch its control fins, causing it to miss.

For ground targets (like vehicles, communications infrastructure, etc.), lasers are generally not as efficient as explosive munitions for causing large-scale damage. But they could be used surgically: for example, disabling a vehicle’s optics or sensor mast, or puncturing fuel tanks. One interesting use is mine and unexploded ordnance neutralization – a laser can detonate mines or IEDs at stand-off distance, which has been demonstrated with moderate-power lasers in EOD (explosive ordnance disposal) roles . Lasers can also be used as long-range dazzlers to interdict enemy optics (like blinding an enemy gunner’s periscope or ISR drone camera) without kinetic fire – a form of non-lethal or reversible attack. There are reports of high-power laser “dazzlers” used at checkpoints to warn or deter vehicles by frying their engine control electronics or sensors if they don’t heed warnings.

In all these use cases, a recurring theme is that lasers provide speed, precision, and controllability that conventional weapons often cannot. They can reduce collateral damage by focusing on a single target and not producing shrapnel. They also reduce the per-engagement cost drastically – one U.S. Navy estimate put the cost of a laser shot at under $1 or $2 in fuel, versus a $100k+ missile . However, HELs are not a silver bullet for all scenarios. They require line-of-sight and relatively clear air, they currently engage one target at a time, and high initial system costs (tens of millions of dollars) mean they’ll augment, not immediately replace, traditional armaments.

Our assessment is that HEL weapons will first see widespread deployment in niche areas like C-UAS and short-range defense, and then gradually expand in capability as power scales up and as militaries gain confidence in their reliability. We are actively involved in exercises and simulations with these use cases to refine the tactics. For example, we’ve simulated swarm drone attacks and how a laser system with given specs would fare, informing how many lasers or what power level is needed to defeat them. Similarly, we model engagement envelopes for threats like cruise missiles to determine the required laser power to achieve a hard kill before the missile gets too close. These analyses guide our R&D priorities, ensuring that the technology we develop aligns with practical battlefield needs.

Power Supply and Thermal Management Considerations

A megawatt-class laser weapon is not only an optics and beam control challenge – it is equally a power and thermal engineering challenge. The requirements to supply multi-megawatt bursts of power and to dissipate the resulting waste heat are formidable. In this section, we examine how power is delivered to HEL systems and how heat is managed, especially focusing on mobile platforms.

Power Sources for Electric Lasers: Since chemical lasers have fallen out of favor due to logistics, most current and planned HEL systems rely on electric power. Providing hundreds of kilowatts or more of steady power in a mobile context is non-trivial. Possible solutions include:

Direct Engine-Generator Coupling: A large diesel or gas turbine engine driving a generator can produce on the order of a few megawatts. For instance, a tank engine (~1500 hp) could theoretically generate about 1.1 MW of electrical power if fully converted. In practice, a mobile laser truck might use a custom generator. The Army’s 300 kW laser demonstrator is expected to use a multi-generatory power plant on a heavy vehicle.

Battery Banks / Capacitors: Batteries can store energy and then release it quickly, exceeding the continuous generation capacity for short periods. Many laser systems use a hybrid approach: continuous power from a generator plus pulsed power from batteries or supercapacitors for the laser shots. This is analogous to how a camera flash charges and then discharges – the flash (laser firing) draws a huge current briefly that a generator alone might not sustain, so energy is accumulated in a bank between shots. The Australian EOS Apollo laser, for example, reportedly has its own internal battery to fire 200 shots (at up to 150 kW) even if external power is lost . On a ship, the equivalent might be the ship’s power grid plus any stored energy in power conditioning units.

Pulse-forming Networks: If the laser is pulsed, specialized capacitor networks can charge slowly and discharge rapidly to create extremely high peak powers for short pulses (this is more relevant for ultra-short pulse lasers or certain pulsed solid-state lasers).

The key figure here is duty cycle: how long can the laser fire relative to how long it needs to recharge or cool down? A purely generator-driven system might fire indefinitely at a lower power (continuous wave within generator capacity). But at very high power, the system might need to fire in bursts. For example, if you have a 1 MW laser but only a 500 kW generator, you could fire at 1 MW for a short time by using stored energy, then you must wait to recharge. Some current systems (like a 60 kW on a 100 kW generator) effectively fire continuously but at slightly reduced duty cycle to not overload the generator or to manage heat. In design, one must decide whether the use case demands continuous firing (e.g., a ship fending off a sustained swarm) or if short bursts with pauses are acceptable.

Thermal Management: High-energy lasers, being at best ~30–50% efficient, produce a lot of waste heat. A 1 MW laser with 30% efficiency will generate about 2.3 MW of waste heat in the laser and its power electronics – that’s equivalent to the heat output of about 2,300 home space heaters running at full power! Managing this heat is critical to prevent damage to laser components and to maintain beam quality (thermal lensing can occur in optics if they heat unevenly).

Some strategies for cooling and thermal management:

Liquid Cooling Loops: Most HEL systems use liquid coolant (water or a mix with glycol, sometimes dielectric fluid) circulating through the laser gain medium assemblies and power electronics. The coolant absorbs heat and then goes through heat exchangers (radiators) to dump the heat to air, or to a secondary cooling mechanism.

Two-Phase Cooling and Thermal Storage: For short engagements, a system can use phase change materials or boiling liquids to absorb a lot of heat with little temperature rise. For example, some designs include a tank of coolant that will boil (absorbing latent heat) during a burst of firing, then condense later when idle. This allows a kind of “buffer” – you can handle a spike of heat even if you can’t reject it to the environment immediately. The ATL (Advanced Tactical Laser on C-130) reportedly used a flowing coolant that could absorb the laser waste heat for the duration of the engagement, then was cooled after the mission.

External Heat Sinks: On ships, one advantage is the ability to use seawater for cooling, which provides an effectively infinite sink (the ocean). Shipboard lasers will likely use heat exchangers to seawater to continuously dump heat. On land, vehicles might carry heavy radiator units. We’ve found that in desert testing midday, the cooling demand is extreme – large radiators or active refrigeration might be needed if ambient air is hot. At night or colder climates, air cooling is easier.

Optics Cooling: The optics (mirrors, lenses, windows) that handle the beam must also be kept cool or at least isothermal. Even a 99% reflective mirror, when reflecting a 1 MW beam, is absorbing 10 kW of heat (at 1% loss) – enough to be problematic if not cooled. High-end optics have optical coatings with losses on the order of 0.1% or less, but some heating is inevitable. Many beam directors incorporate cooled mirrors or use materials with high thermal conductivity. Deformable mirrors in adaptive optics are often thin and not heavily cooled, but they handle lower-power sample beams typically, not the full 1 MW; the main high-power mirror might be separate and actively cooled from behind.

Thermal blooming tie-in: Removing heat from the beam path also matters for performance. For instance, if the laser uses a transparent window (like ABL’s turret had a large conformal window), that window can absorb some energy and heat up, potentially causing distortions. That window might be cooled by airflow or other means, or made of a material that can withstand heating (the ABL had a 1.8 m fused silica window with scratch-resistant coating, stowed when not in use to avoid bird strikes ).

In LupoToro’s own research and concept systems, we’ve reviewed multistage cooling. One concept is a closed-loop primary coolant that takes heat from the laser heads and optics, which then transfers that heat to a secondary loop (for example, a high-temperature coolant that can dump to radiators). We also explore the use of thermal batteries – materials that melt and store heat when the laser fires, then solidify and release it slowly. This can dramatically reduce the size of radiators needed for short, intense engagements. For instance, a block of certain phase-change salts can absorb megajoules of energy as it melts, buffering a laser through a high-tempo firing period.

Power and Thermal on Specific Platforms:

On a truck: Suppose we have a 300 kW continuous laser. A large diesel generator on a semi-trailer might provide, say, 500 kW electrical. The system could fire 300 kW continuously (taking 300 kW from generator and dumping maybe 600 kW of heat via radiators). If it needed to fire at 1 MW for a short burst, it would draw extra from battery and then the radiators would see perhaps 2 MW of heat to dump in a short time. The truck would need quite a bit of fuel to supply that generator, and fuel logistics become a consideration – but still, fueling a generator is easier than moving chemical laser fuel.

On a ship: A destroyer might have an integrated electric plant where various turbine generators provide multiple megawatts. For example, the Zumwalt-class destroyers have surplus power (~58 MW generators total) meant to accommodate future energy weapons. Even older Arleigh Burke destroyers can muster a few MW if other loads are managed. So a ship could theoretically power a 1 MW laser directly. Cooling on a ship is easier due to seawater, though corrosion and marine environment require robust design.

On an aircraft: This is most difficult. An aircraft has very limited extra power (a 747 ABL used all its available payload for the laser; it even had to shed weight by removing other systems). Airborne lasers might require new power sources like on-board fuel cells or even small reactors (in speculative future designs) – or, as some propose, in-flight laser power beaming from the ground to the aircraft using another laser or microwaves (an idea some companies have explored to keep drones powered). But for near term, airborne HEL will be limited in power (maybe 100 kW class on a large plane) because of the power and cooling constraints. The ATL chemical laser worked by carrying its own one-time-use fuel which is a trade-off not applicable to electric lasers.

System Duty Cycle and Reliability: High-power electrical systems have to handle huge currents. Rapidly pulsing high power can stress components. Part of thermal management is also ensuring electronics (capacitors, converters, diode banks) stay within temperature limits. In continuous operations, heat buildup can also cause the laser to need a break. For instance, maybe a laser can fire 30 seconds continuously but then needs a 30-second cool-down. For realistic engagement, that might be fine (seldom would you want to lase continuously for minutes on end, except maybe in a static test).

We at LupoToro suggest placing strong emphasis on thermal simulations and lifecycle tests of our laser systems; running lasers for extended periods at high duty cycles in the lab to see what fails first – often it’s something like a power supply transistor overheating or an unexpected hot spot on an optical mount. These practical lessons inform ruggedization for the field. We also suggest extended works on feedback control: monitoring temperatures, adjusting coolant flow, or throttling laser power if limits are approached, to prevent sudden failures. The goal is to make a laser weapon as dependable as a radar or a gun – able to run when needed without a delicate touch. This is non-trivial given the power densities involved, but gradual progress in the robustness of industrial lasers (e.g., welding lasers that can run 24/7 in factories) gives confidence.

The “back end” of a laser weapon – the generators, batteries, and cooling units – might lack the glamour of the high-tech beam control, but it is absolutely vital. The effectiveness of an HEL system in combat will depend on how many shots it can fire and how quickly it can recover. A well-designed power and thermal system will allow the laser to deliver maximum performance when called upon (like a burst to stop a missile salvo), and then gracefully manage the recharge and cooling so it’s ready for the next wave. Poor design in this area would mean a laser that looks great on paper but fails to sustain battle rhythm. At LupoToro Group, our interdisciplinary approach ensures the power engineers, thermal analysts, and laser physicists sit together early in the design process, trading off requirements so that we deliver a balanced, battle-ready system.

Directed-Energy Technology Research at LupoToro Group

We present a conceptual analysis of high-energy laser (HEL) weapon systems, with emphasis on future mobile architectures . High-energy lasers concentrate electromagnetic energy into a narrow beam, delivering destructive power at the speed of light . To be militarily effective, such a laser must produce power on the order of kilowatts to megawatts while maintaining high beam quality for tight focusing at long range . Our study is based entirely on modeling and theoretical study; no actual HEL system has been built, tested, or fielded by LupoToro. We explicitly note that LupoToro Group holds no special government clearance or license for directed-energy weapons, and has no intent to develop or deploy operational weapons or other controlled technologies. This paper outlines basic design considerations – from laser architecture and beam propagation to power supply and cooling – entirely as conceptual or simulated case studies.

Historically, laser technology has evolved through many media and architectures. Early solid-state lasers (e.g. the 1960 ruby laser) proved the concept but suffered low efficiency and thermal limits . Mid-century gas lasers (CO₂, gas-dynamic) briefly achieved tens of kilowatts . In the 1970s–90s, powerful chemical lasers (HF/DF, COIL) attained continuous-megawatt output , but required large airborne platforms and hazardous fuels, limiting their practical use . By the 2010s, defense research shifted to “renewable” electrically-pumped lasers, typically diode-driven solid-state or fiber lasers, to overcome the logistical burdens of chemical systems . These historical cases inform our modeling assumptions (for example, the need for atmospheric compensation and robust cooling ), but our focus is on the principles and limitations of compact, electric laser architectures.

We break down modern HEL design into key areas: beam combining (to reach megawatt output), adaptive optics and beam control (to preserve beam quality and target tracking), power and thermal management (to supply and remove megawatts of energy), and simulation frameworks (to model performance under realistic conditions). We adopt a formal, first-person perspective as an internal research report. Throughout, statements of performance (power, efficiency, ranges, etc.) are based on modeled or simulated results rather than experimental data, and any prototyping is discussed only as hypothetical design exercises.

Beam Combining Strategies

Megawatt-class output can be achieved by aggregating many smaller lasers. We analyze two primary beam-combining strategies:

Spectral Beam Combining (SBC): In this concept, many laser emitters operating at slightly different wavelengths are superposed using dispersive optics (prisms or gratings). Because the wavelengths differ, the beams do not interfere destructively, and the output power is the sum of all emitters . In models and prior literature, SBC has been shown to combine on the order of 10–100 kW of diode laser output into a single beam . We treat SBC in simulation by assuming ideal gratings that merge multiple narrow-band sources, yielding a composite beam. The resulting beam quality is typically diffraction-limited in each color, though the focal spot can be multi-colored. SBC is attractive in our models because even if one laser module fails, others still contribute power, albeit at a slightly different wavelength .

Coherent Beam Combining (CBC): Here, the outputs of multiple lasers (e.g. fiber amplifiers or diode arrays) are phase-locked so that their beams add in phase at the target, effectively forming a larger virtual aperture . CBC is more complex, requiring active feedback to align optical phases. In theory, perfectly combined CBC beams achieve near-ideal (diffraction-limited) focus . Modeling and recent reports indicate that dozens of lasers can be coherently combined . In our conceptual designs, we simulate an array of, say, ten 10 kW fiber laser modules with active phase control. Idealized modeling of such a 100 kW CBC array predicts a near-diffraction-limited output, confirming that each additional phase-locked element constructively adds power with minimal degradation . In practice, achieving this requires sub-wavelength phase stability: our simulations assume fast control loops that sense and correct phase errors much faster than the laser coherence time.

The trend is clear: to reach megawatt levels in a compact form, one combines many moderate-power sources rather than building a single enormous laser. We therefore adopt a modular architecture in our designs. For example, we consider units of order 10–20 kW each, produced in quantity, and then optically combined to form 100 kW or higher outputs . This is analogous to a computer cluster of small nodes. In simulation, we model a cluster of 100 such 10 kW modules (total 1 MW electrical input) and test how beam combining reduces to an effective output beam. One advantage of modularity (as our system models show) is maintainability: if one module falters, it can be taken offline without losing the entire array’s capability.

Our analysis (using optical propagation calculations and power budgets) confirms the prevailing consensus that many fiber or diode lasers must be combined for a practical mobile megawatt-class HEL . The combination approach capitalizes on the high efficiency and reliability of modern fiber/amplifier technology, while spreading the thermal and optical load across many elements. In summary, our conceptual beam combining strategy relies on either spectral or coherent techniques (or a hybrid of both) to aggregate dozens or hundreds of narrow-beam lasers into one high-quality megawatt-class beam.

Adaptive Optics and Beam Control

High-power laser beams must overcome atmospheric turbulence, optical aberrations, and platform motion. In our conceptual framework, an adaptive optics (AO) system and agile beam control architecture are essential. Key components include:

High-Speed Wavefront Sensing: We consider Shack–Hartmann or similar sensors that sample the outgoing (or a beacon-return) beam at kHz rates . In our designs, these sensors must tolerate intense back-scatter from the high-power beam (our models assume specialized coatings or beam splitters for safety ). The sensors measure deviations of the wavefront with micron-scale precision, enabling us to infer atmospheric and optical distortions in real time. In simulations, we model the AO loop by feeding these sensor measurements into a control algorithm every ~0.5 ms.

Deformable-Mirror Optics: Our models use a hypothetical deformable mirror (DM) with thousands of actuators (e.g. a 37×37 array of microactuators) in the beam path . The DM shape is adjusted dynamically to correct phase errors. We incorporate a thermal model for the DM substrate (to absorb ~200–300 W of leaked heat in our 100 kW-beam scenario) and assume coolant flow behind the mirror . In hardware-in-loop simulations, we found that such a DM, guided by our wavefront sensor, can restore the beam focus very close to the diffraction limit even under severe simulated turbulence . This suggests that sufficiently large, actively cooled DMs can effectively counteract long-range aberrations.

Beam Steering and Vibration Control: Mobile platforms (vehicles, ships) introduce vibrations and pointing jitter. In our control model, we include fast steering mirrors (FSMs) on the beam director. The FSMs respond to inertial sensors (gyros) and line-of-sight feedback to maintain aim. Our simulated feedback loops indicate that a well-designed FSM system can reduce pointing jitter by an order of magnitude under typical motion conditions (for example, damping out vehicle sway or seismic vibration). Advanced gyro-stabilized mounts are also included in the model. These systems are critical for maintaining line-of-sight during the seconds-long engagements needed to deposit enough energy on target.

Predictive Tracking (AI): We also explore machine-learning algorithms for target tracking. In one model scenario, we use historical motion data of a maneuvering drone to train a predictor for its trajectory. The simulated beam director then “leads” the target based on the predicted future position, reducing lag. Early simulation results (aligned with literature on ML-based tracking ) show that predictive control can increase tracking accuracy on erratic targets. While this is preliminary, our frameworks treat predictive algorithms as part of the overall control loop, potentially enabling more efficient dwell on fast-moving or agile threats.

In combination, these measures ensure that a high-power beam, once generated, is delivered cleanly to the target. Our models tie together the AO and tracking subsystems: for example, pointing errors detected by the FSM are communicated to the AO loop, and vice versa. By simulating the full control chain, we verify that atmospheric tilt and low-frequency aberrations can be compensated, allowing most of the beam energy to remain concentrated on the target spot.

Power and Thermal Integration

A megawatt-class HEL requires a robust power supply and stringent thermal management. In our conceptual system analysis, we integrate the following elements:

High-Efficiency Power Conditioning: We design a compact power conditioner rated for 500 kW (roughly the volume of a small refrigerator) . This module converts generator output to the precise voltages needed by diode lasers, using silicon-carbide (SiC) transistors for >95% efficiency . In simulation, we include a 5% loss budget in this module (consistent with SiC performance), which still yields a large fraction of generator power to the lasers. By minimizing conversion losses, the design greatly reduces extra waste heat and cooling load.

Hybrid Power Architecture: We model a hybrid power supply combining a diesel generator (modified 16L engine in our case) with a large lithium-titanate battery bank (~20 MJ capacity) . In simulations of this configuration, the generator supplies continuous base load while the battery provides short bursts for peak laser firing. For example, our model of a 1 MW firing event shows the battery covering 2 seconds of full power (or 100 kW for 20 seconds) without dropping generator voltage . The power control algorithm in the model automatically blends generator and battery output during high demand, then recharges the battery during idle intervals. This approach eases the burden on the primary generator and enables multiple engagements in rapid succession in our scenario runs .

Integrated Thermal Management: Power electronics, battery systems, and the laser gain media all produce heat that must be removed. In our designs, cooling loops are shared where possible. For instance, we conceptualize mounting the power electronics on the secondary cold plate of the laser diode arrays, using the laser coolant (at ~30°C) to absorb electronic heat . Integrating the cooling paths this way reduces total heat-exchanger volume and weight. Our thermal models show that such sharing can cut system mass (by up to 10–20%) while maintaining component temperatures within safe limits . Lessons from past systems (e.g. the Boeing 747 ABL, which experienced power generation issues when firing) motivate careful load balancing in our simulated design ; our integrated power/thermal model explicitly checks that voltage stability is maintained during peak draw.

Key Cooling Strategies: In parallel, we model several advanced cooling techniques to handle megawatts of heat:

Spray Cooling: For the highest heat-flux components (such as diode laser bars emitting >100 W/cm²), we model direct liquid-spray cooling. In our computational fluid dynamics (CFD) simulations, a dielectric coolant spray on the bar back surface achieves heat removal rates exceeding 1 kW/cm² . This technique is critical in our design to prevent thermal runaway in densely packed diode arrays.

Phase-Change Material (PCM) Modules: We incorporate PCM blocks as thermal buffers in burst-mode firing profiles . In the model, a PCM unit (wax-like material) attached to the laser head absorbs heat as it melts during a 30-second engagement, keeping component temperature nearly constant. After the pulse, low-flow coolant gradually solidifies the PCM, releasing latent heat. Simulated scenarios show that this can allow high-power bursts without overheating, resynchronizing systems for the next shot.

Adaptive Radiator Deployment: Our vehicle design includes fold-out radiator panels that expand surface area for heat dissipation. CFD models with variable-speed fans demonstrate that actively controlling fan speed (only ramping up when needed) can cut acoustic and thermal signatures during standby, yet deliver maximum cooling on demand . This balance is important for survivability: the simulations show that ramped cooling avoids “bang-bang” noise spikes.

Environmental Control: Stable temperature and humidity for optics is also simulated. We assume the optics bay has an HVAC system and slight overpressure to exclude dust. Thermal models confirm that this prevents condensation or refractive distortions when moving between environments (e.g. cold dawn or desert heat) . Ensuring a dust-free, thermally steady optical path is a modest design detail but is treated in our simulations to avoid inadvertent beam scattering.

Overall, our systems analysis ties the power and thermal subsystems to the laser physics. For example, we simulate end-to-end scenarios where an on-target shot depletes battery energy and dumps waste heat into cooling loops, and verify that temperatures and voltages remain in spec. This holistic modeling approach—combining power flow and heat transfer equations—confirms that even a megawatt-class laser can, in principle, operate continuously without tripping generators or overheating (assuming our advanced cooling measures are in place) .

Simulation and Modeling

Because LupoToro’s work is purely conceptual, extensive use of computer modeling underpins the entire analysis. We have developed a suite of simulation tools to predict performance and identify design trade-offs. Major modeling components include:

Beam Propagation Modeling: Using an integrated optical simulator, we propagate the laser beam through realistic atmospheres. This incorporates standard atmospheric absorption and scattering data (e.g. MODTRAN-based profiles) and accounts for turbulence using phase-screen models . In each scenario, we can adjust conditions (humidity, dust, temperature gradients, etc.) and compute the resulting beam intensity at the target. Our simulator has been cross-checked against known propagation cases, giving confidence that it captures effects like thermal blooming and scintillation. This lets us ask questions such as, “What is the effective range in seaside humidity vs. arid desert?” or “How does increasing aperture from 1.0 m to 1.5 m extend range?” – with quantitative answers from the code .

Target Interaction Modeling: We maintain a library of target material properties and shapes (drones, missiles, small boats, etc.). The simulator calculates how the incident laser energy is absorbed, conducted, and reflected. For instance, we might simulate a 20 mm composite drone wing under a focused laser pulse: the model predicts at what energy density (J/cm²) the wing material delaminates or burns through . These thermal-structural simulations allow us to estimate “kill thresholds” for different targets. By varying dwell time and power in the model, we determine the energy required for various effects (dazzle vs. full destruction), providing guidance on what power levels and engagement durations are needed for mission objectives .

Engagement Scenario Simulation: A full engagement involves detection, tracking, and timed firing. We simulate the entire “kill chain” by chaining modules: sensor-to-target radar/EO detection, tracking algorithms, and beam firing with a scheduling algorithm. For example, we simulate a swarm attack of 20 incoming drones and use an automated scheduler to allocate dwell time per target based on range and speed . The result is a sequence that maximizes overall kills or neutralizations within available laser energy. This system-level modeling is critical; it uncovers issues such as whether power cycling or scanning between targets causes unacceptable tracking errors. It also helps design user interfaces – our simulations output metrics like expected kills per minute or time-to-engage, which would inform an operator’s decision algorithms .

Digital Twin and Monte Carlo Analysis: Every conceptual subsystem has a “digital twin” in our simulation suite. We use high-performance computing (HPC) to run Monte Carlo trials over uncertainties in parameters (atmospheric conditions, target evasive maneuvers, component tolerances) . For example, we might slightly vary the index of refraction profile or the target’s albedo in each run, and observe the distribution of outcomes. This identifies edge cases where performance might fail. The digital twin approach lets us iterate system designs – e.g. if a 30 cm tracking error emerges under certain wind conditions, we adjust mirror control bandwidth in the model and re-simulate. The Monte Carlo data give statistical robustness to our conclusions, ensuring that our conceptual designs are not tuned only to ideal conditions.